- Homepage >

- Instrumentation >

- Instrumentation Facilities

Instrumentation Facilities

The U.S. Army Electronic Proving Groundís (EPG's) Office of Technology Development makes use of various facilities and laboratories at Fort Huachuca in order to research, develop, produce, and maintain the hardware and software required to meet test instrumentation needs.

Software Integration/Test Lab Overview

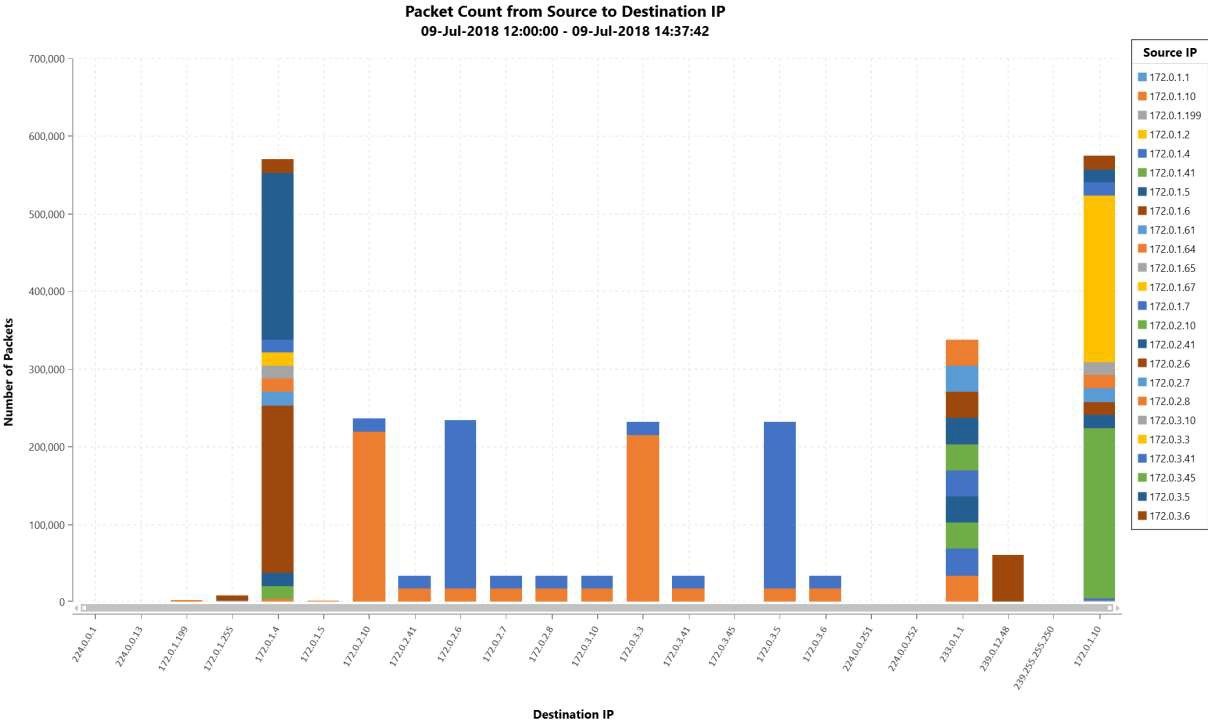

The EPG Software Integration/Test Lab is utilized to conduct Quality Assurance (QA) testing and Configuration Management (CM) of EPG developed software and instrumentation. The Lab hosts a team of experienced QA and CM professionals who continuously maintain a multitude of instrumentation computers and Command, Control, Communication, and Computer (C4) assets. In conjunction with the CM team, the QA test team uses this facility to conduct rigorous software tests on all new and legacy software ensuring the highest standards in software programming are met for EPG products. Additionally, the CM team provides a repository for software capabilities and is the conduit for the release of EPG software products and instrumentation to customers.

The Lab extends its resources and capabilities via the EPG Test Instrumentation /Test Analysis Network (TITAN) to enable distributed testing with Ft Cavazos, TX. This allows the facility to support software developers located at both Ft. Huachuca and Ft. Cavazos.

This facility is also the home to the Instrumentation help desk and customer support for EPG products. Please contact the Instrumentation Help Desk for all instrumentation technical support. They will get you in contact with a lab technician or developer if required.

Email: usarmy.huachuca.atec.list.epg-instrumentation-helpdesk@army.mil

Orion Lab Overview

The Orion Lab is comprised of experienced engineers with a set of comprehensive tool suites capable of providing advanced design and prototyping capabilities. The Lab enhances the effectiveness of EPG's test capabilities by working with test officers to research and design test instrumentation to meet the needs and requirements for a successful mission.

Please contact the Orion Lab for all research and development support.

Email: usarmy.huachuca.atec.list.epg-orion-lab@army.mil

Test Technology Design & Development (T2D2) Lab Overview

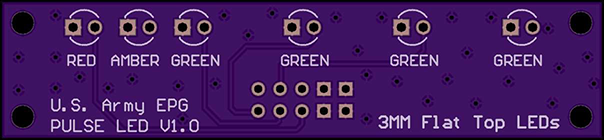

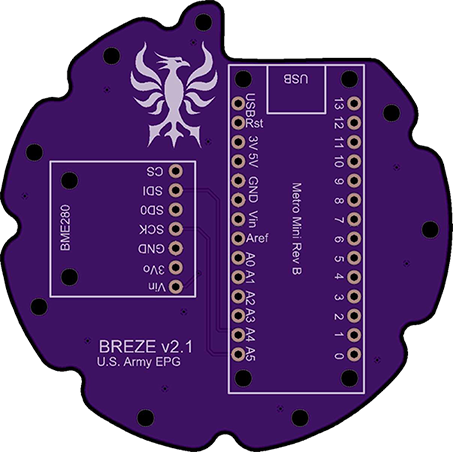

The T2D2 Lab is comprised of experienced technicians with comprehensive skillsets to provide advanced development, manufacturing, and equipment repair capabilities. The Lab enhances the effectiveness of EPG's test capabilities by producing and maintaining test instrumentation needed for a successful mission.

Please contact the T2D2 Lab for all development, manufacturing, and equipment repair support.

Design and Development Capabilities

The Orion and T2D2 Lab maintain expertise in electronic and mechanical design, fabrication, and system engineering enabling quick development projects ranging from miniature sensors to large scale jamming systems. Design and development capabilities include:

- Embedded Processor Design and Development

- Printed Circuit Board (PCB) Design, Layout, and Assembly

- Ruggedized and Environmentally Rigorous Enclosure Design and Development

- Ruggedize and Enhance COTS and GOTS Products

- 3D Modeling Computer-Aided Design & Manufacturing (CAD CAM)

- 3D Printing Design and Development

- Powder Coating

- Cable Fabrication

- Low-Pressure Injection Molding

- Prototype Design and Development

- Portable Instrumentation Design and Development

- Mounting and Fixture Design and Development

- Laser Cutting, Etching, and Engraving

Characterization Capabilities

The Orion and T2D2 Labs are equipped to perform characterization testing on systems, in various stages of development. Early characterization testing can identify potential engineering flaws as well as give validity to a system design before testing at other EPG facilities.

- Thermal Chamber Pre-Compliance Check

- Electromagnetic Compatibility (EMC) Pre-Compliance Check

- Cable Integrity Check

- Size, Weight, and Power (SWaP) Characterization

Laboratory Equipment

- 5 Axis Haas UMC-750 CNC Universal Mill

- 3 Axis Fryer MC15 CNC VMC Mill

- Chicago Sheet Metal Break

- Chicago Sheet Metal Shear

- Moldman 4000

- Full Spectrum Dual CO2 Laser Cutter

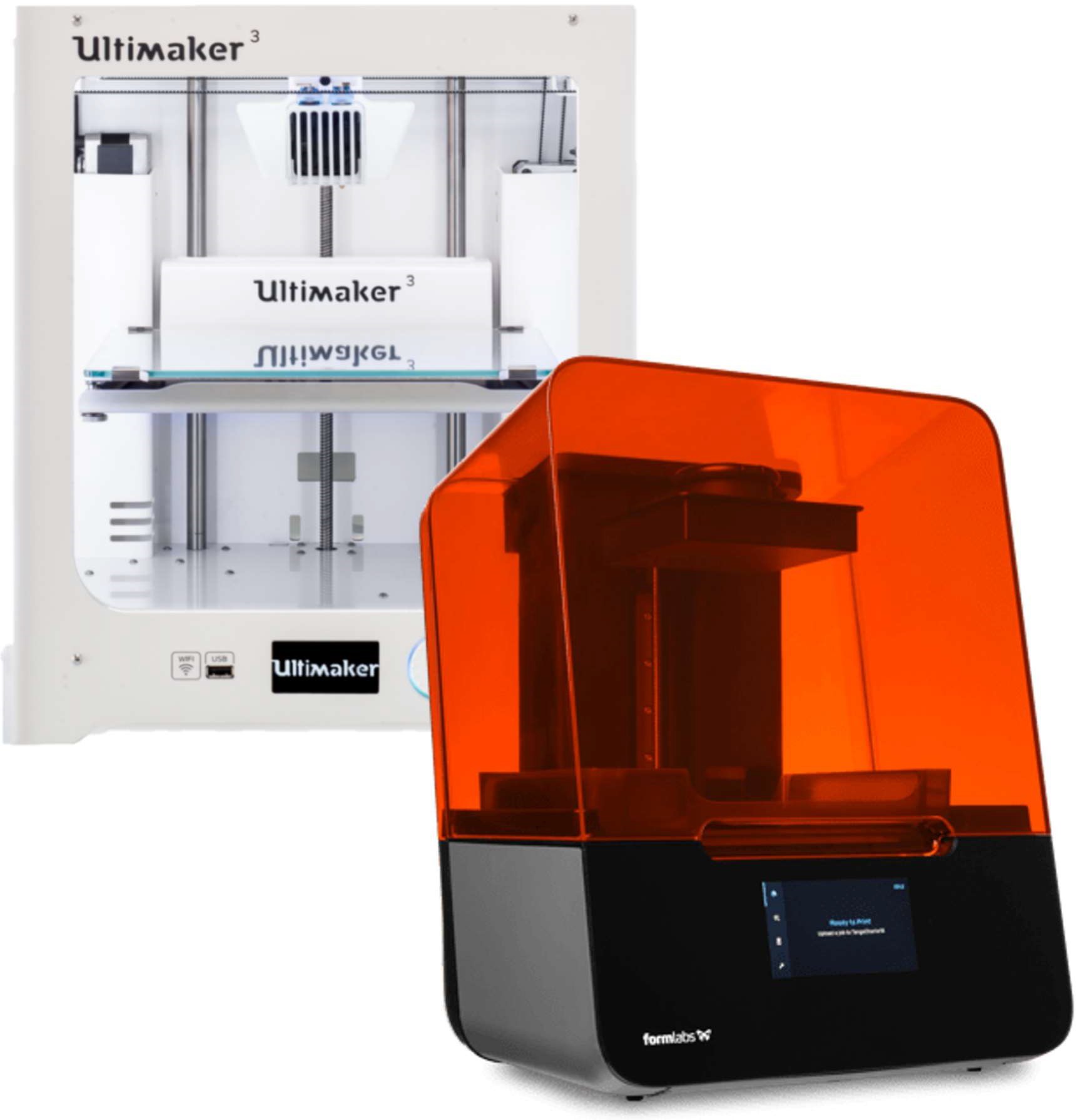

- FormLab 3D Printers

- Ultimaker 3D Printers

- Voltera PCB Printer

- Raymond RF QuietBox

- RF Shielded Chamber

- Fluke Thermal lmager

- Various Scopes and Other Precision Test Equipment