Save a Gallon, Save a Life

Aaron D. Steininger

Test Officer, Force Sustainment and Chem/Bio Protection Branch, Soldier Systems Division, Warfighter Directorate

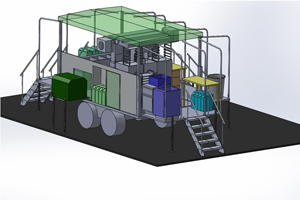

Diagram of BK.

Energy-efficient field kitchens get cooking at ATC.

Cut convoys - cut casualties.

When it’s time to fill ‘er up, we usually think with our wallets. However, the cost of supplying fuel (and water) to our forward troops is measured not simply in dollars, but in lives. Every fuel and water resupply convoy exposes active military personnel to the risk of ambush and improvised explosive device (IED) attacks. In Operation Iraqi Freedom, a casualty occurred an average of once in every 38 fuel convoys; in Operation Enduring Freedom, once in every 24. Between 2003 and 2007, that totals 188 casualties in Afghanistan and 8,858 casualties in Iraq -- more than 9,000 casualties, just for five years’ worth of fuel and water -- a statistic that cannot be quantified with a dollar figure.

The U.S. Army Test and Evaluation Command’s U.S. Army Aberdeen Test Center (ATC) is immersed in testing new energy-efficient systems and upgrades. In recent years, ATC has tested a shower water reuse system to reduce water consumption, solar panels to reduce energy consumption, and fuel-efficient generators and micro-grids to reduce fuel consumption.

The Force Sustainment and Chem/Bio Protection Branch recently began testing two large-scale energy-efficiency projects for Product Manager - Force Sustainment Systems (PdM-FSS). The first is the battlefield kitchen (BK), which will replace the 1970s-era mobile kitchen trailer (MKT).

The mission of the BK will be to provide cooking capability immediately behind our front lines. Both the MKT and BK burn common battlefield fuels to heat food. The BK will be 20 percent more energy-efficient by using restaurant-quality appliances to replace the open-burner, camp stove-like MKT. Each BK will be able to feed 300 military personnel three meals per day, and the Army plans to purchase 1,500 BKs. ATC and the Natick Soldier Research Development and Engineering Center (NSRDEC) have begun testing BK appliances. After testing, the appliances will be integrated into the BK, and the full BK will return for testing in Fiscal Year 2018.

The second energy-efficiency test project is a hard-walled shelter for Force Provider Expeditionary (FPE) rapidly deployable Life Support Modules (LSM). The Energy-Efficient Rigid Wall Module (E2RWM) will supplement the current softwall FPE LSMs and will provide a 30 percent energy savings.

The E2RWM will contain all of the shelters needed for 150 personnel, including billeting, administrative, latrine, laundry, kitchen, dining, and shower capabilities. Twenty-four E2RWMs will be produced to replace 24 of the softwall FPE LSMs. Depending on the operational environment, the E2RWM may be deployed in lieu of the softwall FPE LSMs.

ATC tested competing E2RWM shelters last year to narrow the selection field in preparation for sequential testing of the selected E2RWM shelters over the next five years. Currently, ATC is testing the billeting shelter.

Once these energy-efficient systems are deployed, the Army will save fuel and reduce the need for fuel convoys. That means fewer risky missions for our active-duty military personnel.

You are now leaving www.atc.army.mil and entering another site. You will automatically be forwarded to the target page within five seconds.