- Homepage >

- News

Dugway News

DPG Chemists Develop New Analytical Method for CWA

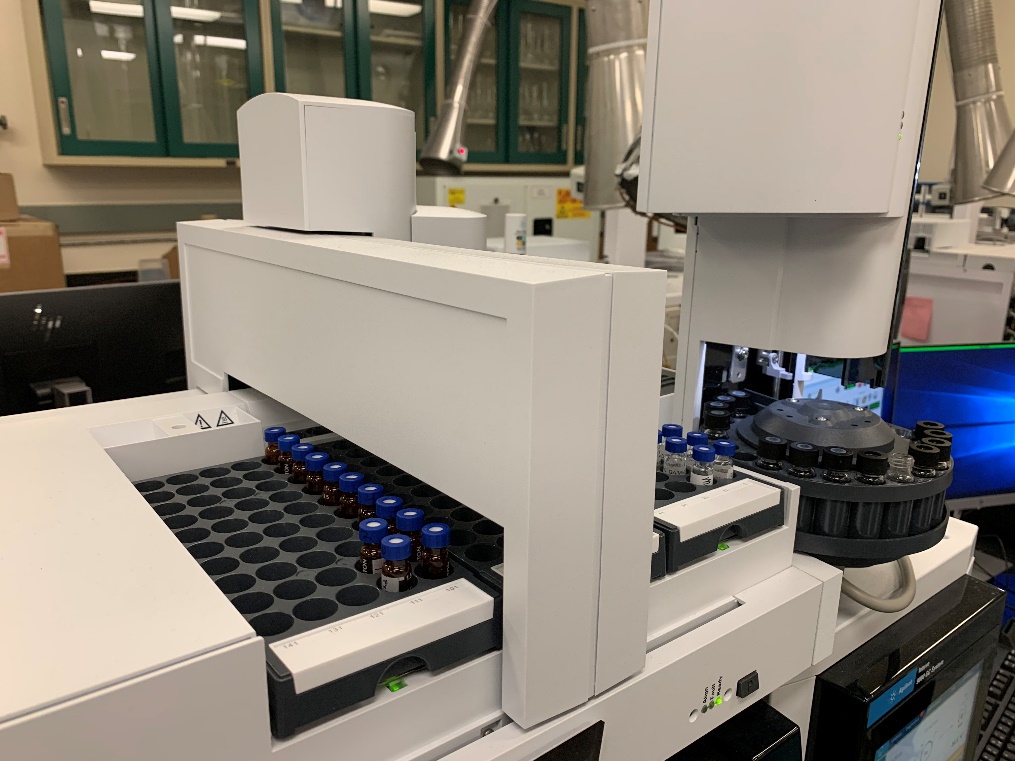

Dugway Proving Ground chemists have developed a new method for solid sorbent tube (SST) analysis of chemical warfare agents (CWA). The innovative approach is to analyze an eluate from the SST using a Gas Chromatography Triple Quadrople Mass Spectrometry (GC-QQQ) instead of thermally analyzing the SST using a Gas Chromatography-Flame Photometric Detector (GC-FPD). The end result

“We have not seen any external reports about analyses of chemical warfare agent eluted from the SST using the GC-QQQ or actual studies to prove that it is a viable process to be utilized in supporting tests,” noted Dr. Richard Phan, Chemical Analytical Branch Chief.

The GC-QQQ is a highly sensitive instrument. Chemists Jeremy Jex, Hannah Line and Travis Losser, with the help of Phan, took on the extensive work to successfully develop quantitative methods for ultra-trace analysis of traditional CWA, such as nerve agents GA, GB, GD, GF and VX and mustard (HD) blister agent.

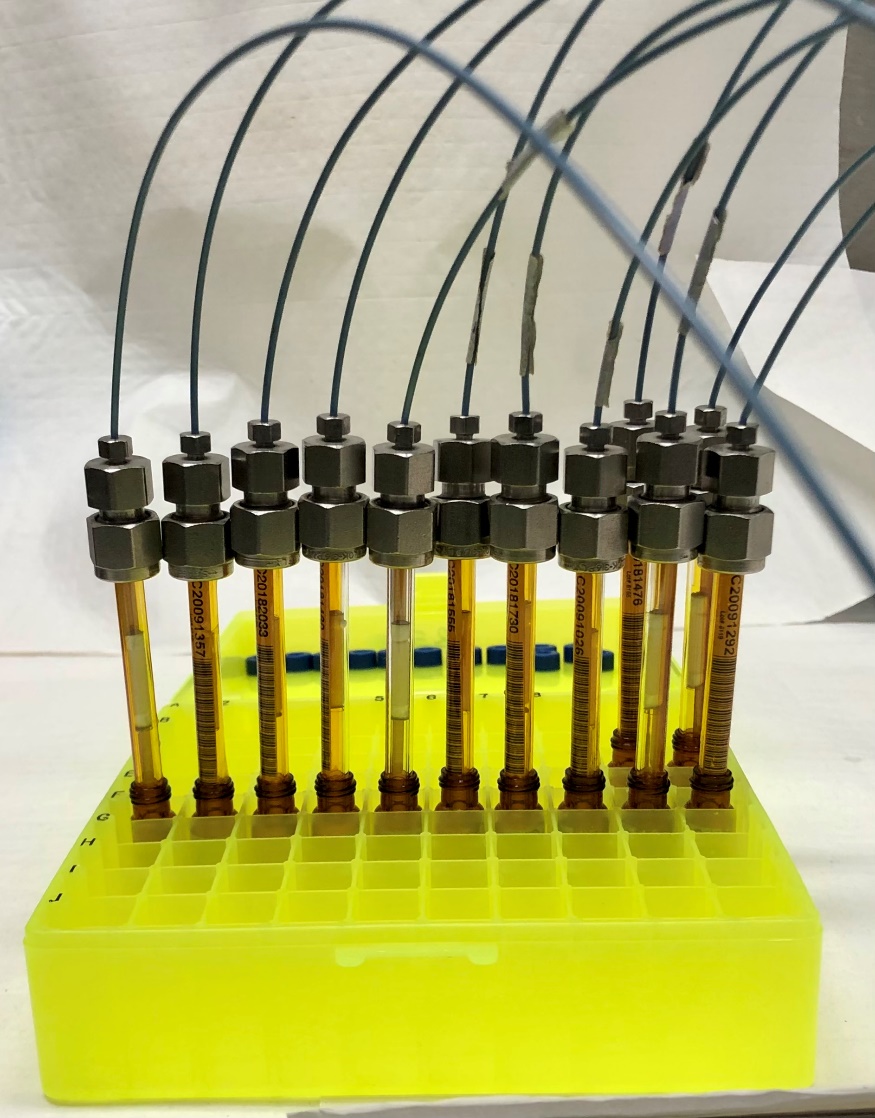

The group had to develop acquisition models for the new instrument, including the method detection limit and the limit of quantification, for each chemical agent. They validated their standards and quality control samples, running a calibration curve on the GC-QQQ to determine the instrument’s official limits. Once that was completed, the group conducted CWA recover efficiency studies from the elution for each agent. The elution method pulls the solvent through the SST to extract CWA into a vial.

“The extracted CWA from the elution were found to be around 96 percent efficient,” shared Line. “Techniques like this that can detect chemical warfare agents at lower levels help ensure better quality of testing and give us capabilities we didn’t have previously.”

Additional benefits of using the GC-QQQ include ease of operation and increased output because it bypasses the need for a confirmation/transfer tube, since the mass spectrometer is the confirmation.

“We wanted to get away from thermal desorption using GC-FPD because it is labor intensive and can’t be automated so it requires an analyst to be with the instruments the whole time,” said Jex. “This new extraction method is much less labor intensive.” The GC-QQQ coupled with an autosampler allows up to 150 samples to be sequentially analyzed in one completely unattended run, “increasing productivity and providing time to work on data packages instead of manually inserting transfer tubes one by one,” Jex noted.

Instead of a transfer tube, the new elution method provides another advantage. “The solvent can be stored and reanalyzed with various instrumentation and multiple analyses,” said Losser, who created the methodology for the new extraction process. “With the thermal desorption method, there is no remaining sample for reanalysis. It’s a one-and-done analysis.”

Now that chemists Jex, Line, Losser and Phan have proven the GC-QQQ is a viable method for chemical warfare agent analysis, it can be used to support future tests. The group will present their findings in early March during a virtual chemical analytical technical conference.

Project of the Year

A project utilizing unmanned aircraft systems (UAS) to monitor golden eagle nests at Dugway Proving Ground (DPG) has won national recognition. The project was named the 2020 Resource Conservation and Resiliency Project of the Year by the DoDs Environmental Security Technology Certification Program (ESTCP).

DPG is home to multiple breeding pairs of golden eagles, which are protected under the Bald and Golden Eagle Protection Act and the Migratory Bird Treaty Act. Because of these regulations, military testing and training activities can be restricted if they risk disturbing active eagle nests. Therefore, it is vital for Dugway Proving Ground, and similar military testing and training ranges, to know the location and status of eagle nests.

For two years during the breeding season, the project team monitored DPG's eagle nests using three observation methods: an on-the-ground human observer, a military UAS and a small UAS (sUAS). The three methods were compared against each other to determine which one offered the most benefits. Researchers found the sUAS to be an extremely useful tool, able to quickly identify nests and take photographs to help determine the age of the eagles, which is an important criteria when deciding whether mission operations can safely continue.

Simply being able to monitor adults and more accurately determine where they are in the nest-to-hatch process allows military activities into additional locations that have traditionally been limited, explained wildlife biologist, Robert Knight, Natural Resources Program Manager at DPG.

The results of the two-year project, said Knight, will be made available through a final technical report and a guidebook for range managers that will focus on the use of sUAS.

The results will inform range managers and natural resource managers on the best way to leverage technology to reduce range restrictions while meeting eagle stewardship responsibilities and critical mission objectives.

Being able to use a military UAS, in this case an MQ-1C Gray Eagle, was made possible by the Rapid Integration and Acceptance Center (RIAC), a DPG tenant that conducts end-to-end testing of UAS.

Ron Delgado, RIAC Product & Operational Safety Lead, who was part of the project team, pointed out other long-term benefits. The opportunity for RIAC to support this effort impacts all missions on Dugway. This project provides students being trained in unmanned aircraft systems the challenge of being given a grid coordinate and then identifying a difficult target. This will enhance UAS operator abilities to support difficult missions when deployed.

In addition to RIAC and the DPG Natural Resource Office, the project team included Select Engineering Services, HawkWatch International, and the Army Threat Systems Management Office.

DPG Joins Lab Battle Against Coronavirus

The BioTesting Division (BTD) will soon start a study to determine how severe acute respiratory syndrome coronavirus 2 (SARS-CoV-2) is transmitted among airline passengers. The efficacy of practices to decontaminate the virus that causes COVID-19 will also be studied.

A section of a jet airliner fuselage, containing three rows of seats, five windows, overhead storage bins, armrests and folding seat-back trays was trucked to Dugway Proving Ground for the test. Outside air will pass through the fuselage’s intact ventilation system, to study interior airflow and how the virus is disseminated.

SARS-CoV-2, which causes the COVID-19 disease, will be used only in industrially filtered and sealed labs at BTD. MS2, a virus that infects E. coli bacteria but is harmless to humans, will simulate SARS-CoV-2 outside the labs as required. The test will be conducted from mid-November through March 2021.

“MS2 has been used a lot in these kind of decontamination studies,” said Test Officer Angelo Madonna of BTD, which resides on DPG, but it is a tenant unit under the command of the CCDC Chemical Biological Center.

Two commercial sprayers and two commercial liquid disinfectants will be tried in different combinations on surfaces in the passenger area to gauge effectiveness. “They also want to know if the virus can be disinfected when it’s airborne,” Madonna said.

Part of this trial includes a machine that replicates the release of particles by human coughing, sneezing and speaking and is combined with artificial saliva developed in the lab.

A variety of trials will explore, using the MS2 simulant, how SARS-CoV-2 travels within a commercial airliner’s fuselage. The most practical and effective means to decontaminate, hoping to make airline travel safer without long delays and setup, will also be examined. This includes ultraviolet light’s effectiveness against aerosolized viruses.

Also, samples of fabric and plastic taken from the fuselage will be contaminated in the filtered lab with the MS2 virus, then disinfected with current equipment and methods.

Ultimately, the varied testing conducted at BTD is expected to advance our understanding of the transmission and decontamination of SARS-CoV-2, which has infected more than 47 million people worldwide with the COVID-19 disease.TECFT will return to Dugway Proving Ground and the West Desert Test Center in 2022 and could, under the direction of the Deputy Under Secretary of the Army for Test and Evaluation, be expanded to support additional areas of interest such as protection and decontamination.

TECFT Highly Successful

Dugway Proving Ground is celebrating the completion of the first—and very successful—Technology Experimentation and Characterization Field Trials (TECFT). A new two-grid system, an experienced and hardworking DPG team, and favorable weather all came together to produce a worthwhile and productive event for participants.

“We conducted 140 trials during the two-week event,” said Adam Drochner, West Desert Test Center (WDTC) test officer, who was the DPG TECFT lead. “A new two-grid system was developed for outdoor testing; there was one grid to conduct biological trials and a separate grid to conduct chemical trials. This new setup was very efficient and allowed for nearly double the number of field trials than was executed during past events.”

Built on the success of previous S/K Challenge events conducted at Dugway Proving Ground, TECFT allows cost-effective testing of chemical and biological detection technologies. This year’s two-week event kicked off on Sept. 27, 2020, and took place in the Joint Ambient Breeze Tunnel and the Active Standoff Chamber the first week and then moved to outdoor field testing at Target S for the second week of trials.

Speaking to the DPG test team and participants during the nightly safety briefing near the end of week two, Col. Scott Gould, Commander of Dugway Proving Ground, expressed his satisfaction. “We’ve had good trials and good results. Most importantly, we are moving these technologies forward and that’s what this is all about.”

TECFT’s success didn’t come easy. COVID-19 impacts included a four-month delay, and even with a later start date, some registered teams still canceled because of travel or safety restrictions. Some of the teams that did come had to limit their number of attendees. Despite these challenges, seven teams, including one private industry and six government agencies, participated. More Department of Defense (DoD) programs participated this year than previously.

One of the participating DoD programs was the Joint Program Executive Office for Chemical, Biological, Radiological and Nuclear Defense (JPEO-CBRND), which brought its CBRN Sensors Integration on Robotic Platforms (CSIRP) technology to TECFT, a “rapid prototyping and fielding effort focused on miniaturizing and integrating modular CBRN sensor solutions,” according to a program publication.

When asked about the value of TECFT for testing their technologies, a member of the CSIRP test team responded, “We’re getting some data that we’ve never seen before.” Each TECFT participant collected their own data, comparing it against the WDTC test referee system for accuracy. The WDTC test referee system relies on multiple technologies to provide a digital picture of the simulant agent clouds and near real-time monitoring data so test teams know what their detection technology should be seeing. Said another test team member who came to TECFT to improve their detector's algorithms, "This has been a good learning experience for us."

Drochner said making TECFT a success was a team effort. “I want to thank everyone involved in TECFT for making it a successful event,” “It takes a lot of people to make this happen and make it beneficial for the participants.”

TECFT will return to Dugway Proving Ground and the West Desert Test Center in 2022 and could, under the direction of the Deputy Under Secretary of the Army for Test and Evaluation, be expanded to support additional areas of interest such as protection and decontamination.